Wind power is really taking off, isn’t it? As demand for clean energy grows, wind turbines are becoming a common sight across the United States. If you’re new to the topic, it helps to first understand [what wind energy is and how it works] before diving deeper into how these systems are maintained and optimized.

Today, AI-driven wind turbine maintenance is transforming the way U.S. wind farms operate. By reducing unexpected downtime and improving overall energy efficiency, artificial intelligence is replacing the old trial-and-error approach that once relied heavily on manual inspections. In the past, this guesswork wasted both time and money.

Now, advanced data analytics and automation are powering smarter wind turbine optimization techniques. From predictive maintenance to performance monitoring, making wind farms more reliable, efficient, and cost-effective than ever before.

Here’s What’s Important

- AI wind turbine maintenance is making turbine smarter by using live data to guess when problems might pop up, so there are fewer breakdowns and less money spent on urgent fixes.

- Instead of waiting for stuff to break, AI helps plan maintenance when the turbines aren’t making much power. That way, the energy keeps flowing and you don’t lose as much money.

- Digital twins—virtual versions of the real turbines—let us test fixes and upgrades without risking the real deal. This helps the turbines run longer without stopping.

- New AI tools can team up with older wind farm setups, so you don’t have to swap everything out. This makes it easier to get the perks of AI without a complete redo.

- With AI, there are fewer risky manual checks and better care for turbine parts, which keeps workers safer and helps the turbines last longer.

Revolutionizing Wind Turbine Operations with AI

Why We Need AI Wind Turbine Maintenance

Wind farms are getting bigger and more complicated. Keeping all the turbines up and running is tough, and just waiting for something to break isn’t good enough anymore. When a wind turbine stops working when it’s not supposed to, it can cost a lot of money. You lose power and have to pay for repairs. Parts like gearboxes and blades can wear out slowly, so it’s easy to miss problems until they’re big. A lot of older wind farms still use systems that can’t tell you what’s happening right away. That’s why we need smart wind energy solutions to watch what’s going on and fix stuff before it gets really expensive.

How AI Helps with Wind Farm Maintenance

AI is a game-changer for taking care of wind turbines. Think of it as giving each turbine its own doctor who checks on it all the time and knows when it might get sick. AI systems use data from sensors on the turbines—things like shaking, temperature, and wind speed—to see tiny changes that people might miss.

Here’s a quick look at how AI helps:

- Watching all the time: AI keeps an eye on turbines 24/7, looking at data as it comes in.

- Finding problems early: It can see when something’s starting to go wrong, like a bearing wearing out, way before it breaks down.

- Checking things fairly: AI can look at pictures and data from inspections, so there are fewer mistakes, and things are checked the same way every time.

Basically, we’re switching from fixing things after they break to taking care of them ahead of time. It’s about keeping turbines running well and for longer. Eberdrola’s AI wind turbine maintenance is an example:

What they do:

- Avangrid, which is Iberdrola’s U.S. subsidiary, is rolling out a generative AI tool called “First Time Right Autopilot” to assist the technicians at its American wind farms.

- The AI system works using Amazon Bedrock models through Amazon Web Services (AWS).

- It’s part of the mobile devices used by field technicians and can be turned on with voice or text.

- When there’s a turbine problem, the AI gathers info, figures it out, and gives the technician repair steps, documentation, or training videos right away.

- This means quicker fault finding, less downtime, and better operations for Avangrid’s wind setup.

This shows how AI tools are changing wind turbine maintenance in the U.S.

AI in Action

This isn’t just a cool idea; AI is already making a big difference. Companies are seeing real wins—less surprise downtime and lower repair costs. Check it out:

- One study showed that using AI to find unusual activity in a wind farm cut operational costs up to 70% and made equipment last around 20% longer.

- A look at digital twins and AI in wind farms showed that these systems can spot tiny issues and point them out before they cause a breakdown.

- One study estimated that using AI to handle wind farm stuff could make energy production 10–15% better and cut down on manual inspections by about 30%.

These aren’t small wins—they’re big changes that are helping the wind industry grow and be more reliable. It’s about making wind power cheaper and something people can count on.

Advanced Monitoring and Fault Detection

Keeping wind turbines in good shape is hard work, and it used to be a guessing game. People would fix stuff when it broke or just on a schedule. That meant fixing things that didn’t need it or waiting too long to fix what did. AI is changing how we keep an eye on these machines.

Real‑Time Sensor Data Analysis

Imagine the turbine has tiny doctors inside, always checking on it. These doctors are sensors, and they collect data on things like vibration, temp, oil, and electricity. AI looks at all of this nonstop, making sense of it all. It finds patterns that people might miss or that show up slowly. This info helps us see how healthy everything is.

Izomind: Spotting Problems Early in Wind Farms

- Izomind’s platform uses AI to find unusual activity in data from wind turbine sensors, like vibrations and temperature.

- They say one study showed unplanned downtime dropped by about 70%, and parts lasted around 20% longer.

- Even though they don’t always name the wind farm, this shows how AI can change how we take care of wind turbines, moving from fixing things after they break to watching for problems ahead of time.

- This could be a general example of how AI helps wind farm operators across the board.

Early Detection of Component Failures

This is where AI is super helpful. It looks through all the data and finds small problems way before they become big ones. If the vibration in the gearbox changes a bit, it might mean a part is wearing out. Instead of waiting for it to break and mess up the gearbox (which costs a lot to fix), AI can point it out early. Then, the repair is smaller and cheaper.

Objectivity and Fewer Mistakes

During Checks Let’s face it, people mess up sometimes. If we only trust people to check machines like turbines, they might miss things. AI is more objective, doesn’t get tired or lose focus, and always checks data the same way. That means fewer problems are missed, and checks are more consistent.

Smart Wind Energy Solutions

Wind farms are tricky, and keeping them running well is hard work. Usually, maintenance is just done on a set schedule. Sometimes you end up fixing things that weren’t even broken, or you don’t spot a real issue until it gets bad. But AI can really shake things up. Instead of guessing, now we can use smart tech to find the best time and way to do maintenance.

Smart Maintenance Schedules

AI checks out tons of info – stuff like weather, how much energy is being made, and readings from the turbine sensors. It uses this to guess when maintenance will mess things up the least. Think about it: It’s way smarter to plan a repair when there’s not much wind than to stop a turbine when it’s windy. This smart planning helps keep things running and avoids wasted energy.

An AI-powered Computerized Maintenance Management System (CMMS) has been created especially for renewable energy assets, such as wind farms, by the digital maintenance platform MaintWiz.

The system analyzes performance data from several turbines in real time, plans preventive maintenance, and tracks turbine health using machine learning algorithms.

It maintains digital records of all maintenance operations for compliance and analytics, automates maintenance scheduling, and assigns tasks according to technician availability and priority.

The CMMS platform helps operators take action before breakdowns happen by integrating SCADA data and IoT sensors to detect early warning indicators of turbine problems.

Important advantages include:

- Predictive alerts and optimized scheduling can reduce maintenance costs by up to 20–30%.

- better use of resources, guaranteeing that parts and technicians are available when needed.

- Improved safety because AI minimizes emergency responses and cuts down on turbine downtime in dire situations.

- improved decision-making, including data-driven insights for budgeting and long-term asset management.

Cutting Down on Downtime and Revenue Loss

When a turbine is down when it shouldn’t be, that really hurts the money you make. If it’s not running, it’s not making power, and that’s lost income. AI can stop this from happening by pointing out possible problems early on. If you fix a small issue before it gets big, you can often handle it when you already planned to, or maybe not even have to shut things down at all. Doing things this way means you get more power all the time and make more money.

Lowering Operation & Maintenance Costs

Besides just helping you not lose money, AI also brings down the cost of keeping the turbines going. Instead of checking every single part all the time, AI can figure out exactly which parts might need a look. So, the repair people can put their time where it’s most needed. You also won’t have to replace parts you don’t need and spend less time on checks that don’t find anything. If you do things this way, you use your resources better and save a lot of cash over time.

Using Digital Twins for Better Simulations

A digital twin is basically a virtual copy of your wind turbine or whole wind farm. It’s not just a 3D model; it’s a copy that updates with real data from the real turbines. It acts like the real thing, showing you what’s happening, but in a safe, digital area.

Copying How Turbines Act

These digital twins use data like vibration, temperature, and electrical output, plus past data. AI then uses this info to make the virtual model act like the real turbine when things change. So, if a real turbine vibrates oddly, the digital twin will show the same thing. This lets us see how parts are doing under stress without being there.

Trying Out Maintenance and Upgrades

This is where digital twins are useful. Before you send people to a turbine, you can use its digital twin to test different maintenance plans. Want to see what happens if you change a bearing? You can try that in the digital world. Wondering how a software update might change how it works? Test it on the twin first. This testing helps you find the best plan, guess what might happen, and avoid mistakes on the real thing. It’s like having a crystal ball for your wind farm

Adding AI to Your Wind Farm

So, you’re thinking about adding AI to your wind farm. If you have older equipment, that might seem difficult—but it is easier than you think. A lot of new AI can work with what you already have. It can connect with your old sensors and control software. Because of this, you can get what AI offers without spending too much. What matters is making connections, not changing everything.

Easy to Add to Old Systems

This point is important for your budget. No one wants to replace working equipment just to add new software. Instead, AI tries to be compatible with what you have. Consider this: You’re adding a smart thermostat to an old house. You don’t need to rewire everything. AI can usually work with your current stuff, getting data from sensors and talking to your systems. This saves money, time, and stress.

Making Data Easy to See and Use

For AI to work, data is needed. And the data needs to be easy to get. There are methods to get information that AI needs, even with old systems. This may mean creating better data flow or using tools that act as a bridge between old and new things. The goal is to easily see what the AI is doing and the reasons why it does it. If you see how AI looks at your turbine’s information, you will be more confident in using what it suggests!

Making Wind Turbines Safer and Last Longer

When we talk about wind turbines, you know, the huge ones in fields or offshore, safety is super important. And we want to keep those pricey machines running as long as we can. It’s key to the money and keeping power flowing. AI is helping a lot, making it safer for workers and keeping turbines running well for years.

Less Need to Check Things by Hand

Before, checking a turbine meant someone climbing up, looking at parts, and writing notes. It took forever and was a bit risky. AI changes that. Sensors and cameras send data constantly, so we know how healthy a turbine is without sending people to risky spots so much. Now, there are fewer trips up the tower for basic checks.

Keeping Workers Safe

This goes with the last thing. Less manual checking in tough or unsafe spots means fewer risks for workers. AI can spot possible issues from the ground, so techs can prep for work. They can grab the right tools and gear, knowing what’s up. That cuts down on accidents a lot.

Smart Part fixes for Long Life

No one wants a gearbox or blade to break suddenly. That’s expensive and shuts down a turbine. AI can guess when a part might fail, which is great. Instead of waiting for a break, AI warns us early. So, we can plan fixes when it’s not windy. Fixing small stuff early is cheaper than dealing with big breaks. Smart fixes keep turbines running well and help them last longer, so we get more clean power from them.

AI-powered Wind Turbines Maintenance

Getting AI to work in wind turbine maintenance isn’t always easy. Operators should know about a few potential problems. It takes thought and money; it’s not a simple thing.

System Compatibility Issues

Since many wind farms are older, their equipment might also be old. It can be hard to get new AI tools to work with these older systems. You probably don’t want to replace everything just to use the new AI. Luckily, many AI solutions are made with old tech without big changes. Finding something that fits what you already have is what matters.

Making Sure Data Is Good

AI needs good info to work well. If the data from sensors is bad or wrong, the AI’s guesses won’t be good. It’s like baking a cake with bad ingredients; you will have a bad meal. So, ensure your data collection is solid and the data is clean before using it in the AI.

Training People

AI tools are great, but people need to use them. You need folks who know how to use these systems, read the data, and do what the AI suggests. This often means teaching your current staff or getting new people with the needed skills. It’s a change from old maintenance jobs to data analysis and tech.

Following the Rules

There are rules when dealing with lots of data, mainly from important stuff like wind farms. These include data privacy rules and security stuff. You must gather, store, and use data ethically and legally. Keeping important data safe from hackers is a big deal.

AI’s Role in the Future of Wind Energy

So, what’s coming up for AI in wind power? It’s not just about fixing stuff when it breaks down now. We’re finding smarter methods to guess what could happen and get turbines running even better. The aim is to keep those blades spinning in a good way for as long as we can.

Better Weather Prediction

Weather forecasts are getting better all the time, right? AI is doing that for guessing wind patterns. Smart math stuff can now check loads of info – past wind speeds, air pressure, where things are located – to give us a clearer idea of what the wind will do. This means wind farm bosses can better plan how much power they’ll make and when to fix things.

Next-Level Digital Copies

We’ve chatted about digital twins – but they’re getting even cooler. Think of a computer version of your whole wind farm, not just one turbine. These new digital twins can show how everything acts in different situations. They can also test new ways to fix things across the whole farm and even guess how upgrades might change how well things work. It’s like having a magic ball for your wind farm.

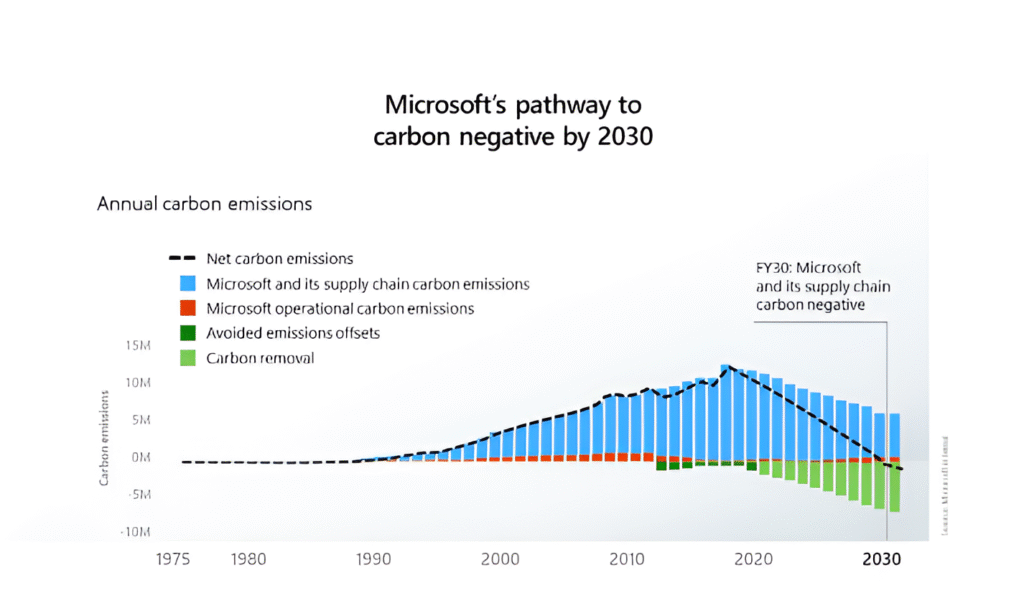

Measuring Greenness

Since the world wants cleaner energy, showing how green we are is a must. AI is helping us measure and tell people about how sustainable we are. By checking repair info and power output, AI can figure out how much less carbon we’re making because we’re running things better and keeping equipment around longer. This is key for companies trying to hit green goals and talk about how they’re doing.

The move to green energy means more turbines, more info, and more stuff to handle. AI isn’t just a nice thing to have; it’s becoming something we need to run these big operations well and save money. It’s about making wind power more able to be guessed, more good, and a larger part of our clean energy future.

The future is now for looking after wind turbines.

What does this mean for AI wind turbines maintenence in the US? AI isn’t just a future thing—it’s changing how we keep those big turbines running well. It’s about spotting issues early, planning upkeep when it’s best, and just making things safer and better. There are still some things to sort out, like getting all the data together and teaching people how to use the new tech, but the path is clear. Using AI- powered wind turbines is how wind farms will stay ahead, save money, smart wind energy solutions, and be a bigger part of our clean energy future. It’s a big change, but it’s already going on.

Frequently Asked Questions

Q1. What’s AI, and how does it assist wind turbines?

A1. AI, or Artificial Intelligence, is basically giving computers the ability to think and learn. When it comes to wind turbines, AI keeps an eye on how they’re doing using sensors. It can catch little issues—like a shaky piece—before they turn into major, expensive breakdowns. This helps get stuff fixed early and keeps the turbines running without a hitch.

Q2. Why is guessing when things might go bad (predictive maintenance) a big deal for wind farms?

A2. Wind farms are full of large, pricey machines. If one goes kaput, it costs a fortune since it stops making power. If we guess when things will break, we can repair them beforehand, saving cash and keeping the farm creating clean power without extended pauses.

Q3. Can AI assist in planning maintenance more smartly?

A3. Yep! Instead of fixing turbines on a specific day, AI can check the weather and how the turbines are working. It suggests fixing them when it’s not too windy, so not much power is lost. This makes sure repairs happen at the ideal time, saving both money and energy.

Q4. What are digital twins in wind power?

A4. A digital twin is essentially a phony version of a real wind turbine on a PC. It shows precisely how the real turbine is running. Engineers can use this phony version to try out new thoughts or see what could happen if something breaks—without endangering the actual turbine.

Q5. Is it hard to add AI to older wind farms?

A5. It might seem complicated, but many AI tools are designed to work with older setups. You often don’t have to swap everything out. These recent tools can hook up with the old tools, making it simpler to get the cool parts of AI without a super big, costly change.

Q6. Does using AI make working on wind turbines safer?

A6. For sure. AI assists in spotting problems from far away, so workers don’t always need to climb way up high or go into small areas for checks. This translates to fewer dangerous jobs for people—and a safer spot overall. Plus, fixing stuff before it breaks means the machines last longer.

Ismot Jerin is the founder and Editor-in-Chief of WindNewsToday, an independent publication covering offshore wind, renewable energy policy, and clean power markets with an analytical focus on the United States and global energy transition.