Last updated: January 2026

As offshore wind expands into deeper waters and new global markets, one comparison is now shaping nearly every major development decision: floating offshore wind vs fixed-bottom offshore wind.

This is not just a technical debate.

The choice between floating and fixed-bottom foundations directly affects project costs, site feasibility, environmental impact, grid planning, and national energy strategy. In many regions, it determines whether offshore wind is possible at all.

While fixed-bottom offshore wind still dominates global installations today, its reliance on shallow seabed conditions places clear geographic limits on future growth. Floating offshore wind, by contrast, unlocks deep-water regions using buoyant platforms anchored to the seabed—bringing offshore wind to coastlines that were previously out of reach.

To understand where offshore wind is heading next, it is essential to understand how these two technologies differ, where each works best, and why both will shape the industry’s future.

Table of Contents

Why This Comparison Matters Now

Offshore wind is no longer a single-technology industry.

As explained in our Offshore Wind Energy Explained – Global Overview, early offshore wind growth focused on shallow seas such as the North Sea. Today, many of those regions are approaching saturation.

New capacity is increasingly coming from:

- Deeper waters

- Longer distances from shore

- Markets with narrow continental shelves

This shift makes the floating vs fixed-bottom offshore wind decision one of the most critical planning questions in the industry today—especially for governments targeting large-scale decarbonization.

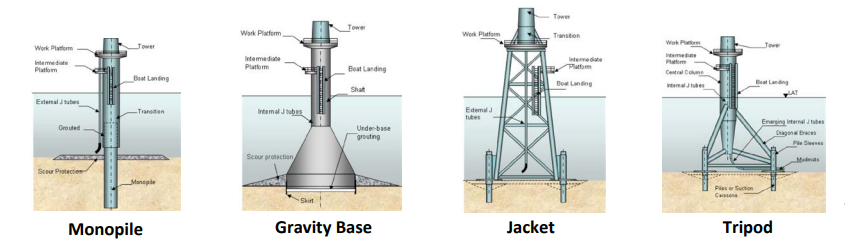

What Is Fixed-Bottom Offshore Wind?

Fixed-bottom offshore wind refers to wind turbines installed on foundations that are physically attached to the seabed. These foundations are designed to remain rigid and stationary throughout the turbine’s operational life.

Common Fixed-Bottom Foundation Types

- Monopiles (most widely used)

- Jacket foundations

- Gravity-based structures

Fixed-bottom turbines are typically deployed in water depths up to 50–60 meters, making them ideal for regions with wide continental shelves such as:

- The North Sea

- The U.S. East Coast

- Parts of China

Because this technology has been deployed for decades, it benefits from:

- Mature global supply chains

- Lower financing risk

- Proven installation and maintenance methods

In established markets, fixed-bottom offshore wind has already reached full commercial scale.

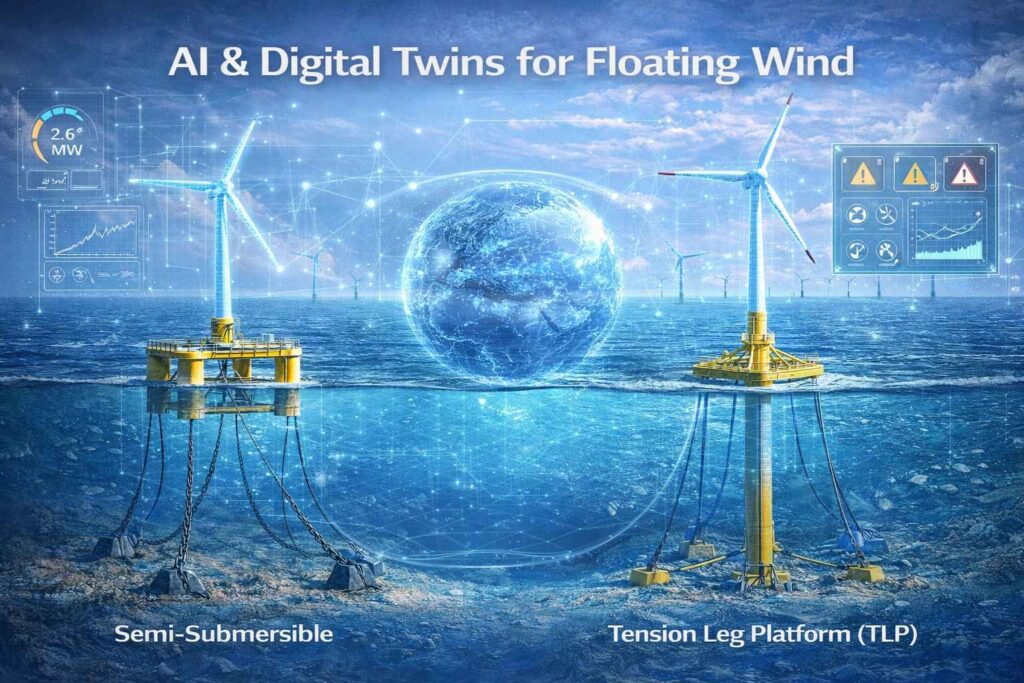

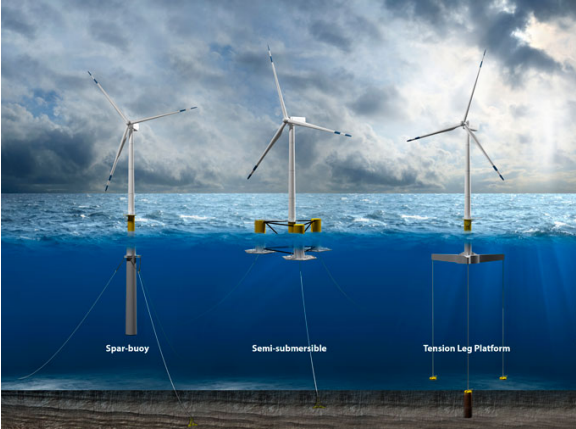

What Is Floating Offshore Wind?

Floating offshore wind uses turbines mounted on buoyant platforms that are anchored to the seabed using mooring lines rather than fixed foundations.

This approach allows turbines to operate in deep waters exceeding 60 meters, opening offshore wind development to regions once considered inaccessible. U.S. Department of Energy research highlights the role of dynamic export cables and advanced mooring systems in enabling floating offshore wind deployment in deep waters.

Key Components of Floating Offshore Wind Systems

- Steel or concrete floating platforms

- Mooring systems adapted from offshore oil and gas

- Dynamic export cables that move with the platform

For a deeper technical breakdown, see our dedicated guide on Floating Offshore Wind Energy Explained.

Floating vs Fixed-Bottom Offshore Wind: Core Technology Differences

1. Foundation Design

| Feature | Floating Offshore Wind | Fixed-Bottom Offshore Wind |

|---|---|---|

| Seabed attachment | Anchored with mooring lines | Physically fixed |

| Water depth | 60–1,000+ meters | Up to ~50–60 meters |

| Platform motion | Limited movement | No movement |

Floating platforms are engineered to absorb wave and wind motion, while fixed-bottom structures rely on structural rigidity and seabed stability.

2. Installation Process

Fixed-bottom installation requires:

- Heavy-lift installation vessels

- Offshore pile driving

- Narrow weather windows

Floating wind installation typically involves:

- Onshore or port-based assembly

- Towing turbines to the site using tugboats

- Connecting to pre-installed anchors and moorings

From a logistics standpoint, floating wind reduces offshore construction complexity but increases reliance on port infrastructure readiness.

Cost Comparison: Floating vs Fixed-Bottom Offshore Wind

Cost remains the largest difference between the two technologies. Cost trends for floating offshore wind remain higher than fixed-bottom projects, particularly due to early-stage deployment and financing risk, according to the International Energy Agency.

Current Cost Profile (2026)

- Fixed-bottom offshore wind: Lower-cost and commercially competitive

- Floating offshore wind: Higher costs due to early-stage deployment

Why Floating Offshore Wind Costs More Today

- Limited supply chain scale

- Specialized mooring and anchoring systems

- Higher perceived financing risk

Why Costs Are Expected to Fall

Floating offshore wind costs are projected to decline as:

- Turbine sizes increase

- Platform designs become standardized

- Manufacturing scales globally

This cost curve is similar to what fixed-bottom offshore wind experienced over the past decade.

Geographic Suitability

Global Wind Energy Council data shows that markets such as Japan, South Korea, and the U.S. West Coast depend heavily on floating offshore wind due to deep coastal waters.

Fixed-Bottom Offshore Wind Works Best In:

- Shallow continental shelves

- Nearshore environments

- Regions with existing offshore infrastructure

Floating Wind Is Essential For:

- Deep coastal waters

- Steep seabed drop-offs

- Regions like:

- U.S. West Coast

- Japan

- South Korea

- Mediterranean countries

In places like California, floating offshore wind is not a choice—it is the only viable option.

Environmental and Visual Impact

Floating offshore wind offers several ecological advantages:

- Reduced seabed disturbance

- Greater distance from shore

- Lower visual impact from coastal communities

Fixed-bottom projects, while well-regulated, can face:

- Greater seabed impact during installation

- Higher visibility near coastlines

Both technologies undergo rigorous environmental impact assessments and long-term marine monitoring.

Grid Connection and Infrastructure

Fixed-bottom offshore wind benefits from:

- Established grid connection models

- Proven offshore substations

- Conventional export cable systems

Floating offshore wind requires:

- Dynamic power cables

- Advanced grid planning

- Flexible transmission systems

As offshore wind capacity expands globally, grid upgrades will be required regardless of foundation type.

Which Technology Has the Bigger Future?

The future is not a competition—it is a combination.

- Fixed-bottom offshore wind will continue expanding in shallow-water regions

- Floating offshore wind will drive growth in deep-water markets

Floating offshore wind is not replacing fixed-bottom wind. It is extending offshore wind into regions that were previously unreachable. Together, they form a complementary pathway toward large-scale decarbonization and energy security.

Frequently Asked Questions

Is floating offshore wind better than fixed-bottom?

No. Floating offshore wind enables deep-water deployment, while fixed-bottom remains cheaper and proven in shallow waters.

Why is floating offshore wind important?

It unlocks offshore wind potential in regions where fixed-bottom foundations cannot be installed.

Will floating offshore wind become cheaper?

Yes. Costs are expected to decline significantly as deployment scales and supply chains mature.

Which countries need floating offshore wind the most?

The U.S. West Coast, Japan, South Korea, and Mediterranean nations depend heavily on floating offshore wind.

Ismot Jerin is the founder and Editor-in-Chief of WindNewsToday, an independent publication covering offshore wind, renewable energy policy, and clean power markets with an analytical focus on the United States and global energy transition.