Teesside, 15 July 2025 — RWE has reached a significant construction milestone at its flagship Sophia offshore wind farm with the 100th steel monopile foundation for a project located on Dogger Bank, 195 kilometers off the UK’s north-east coast – now the latest to be successfully installed, marking the end of a complex 14-month offshore foundation campaign.

When operational, the 1.4 gigawatt (GW) project will have enough clean electricity generation capacity to power 1.2 million typical UK homes annually, further supporting the UK’s renewable energy targets and energy security.

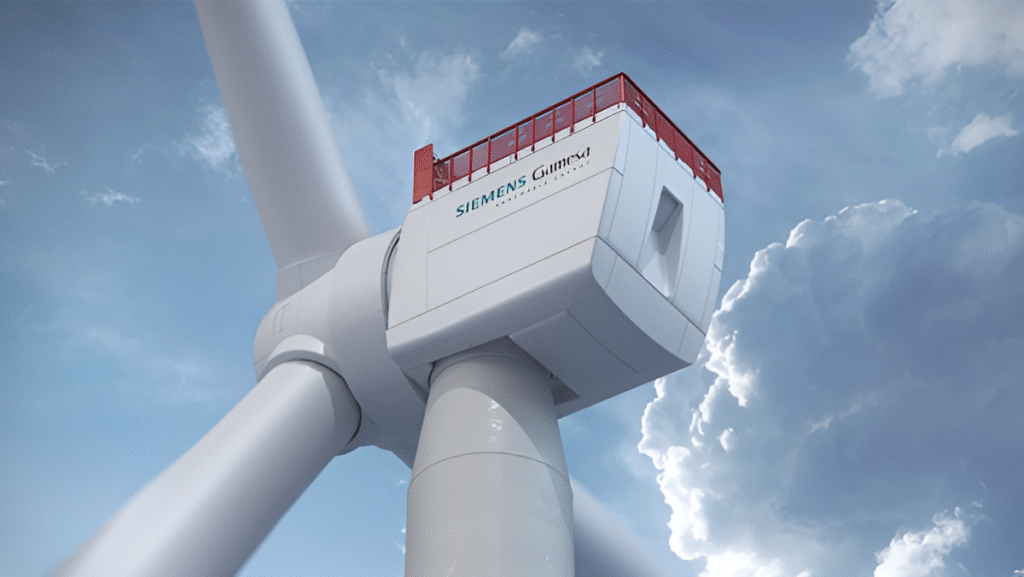

Dutch marine contractor Van Oord led the foundation installation operation under a comprehensive EPCI (engineering, procurement, construction and installation) contract. The company used its upgraded jack-up vessel Aeolus, which was equipped with a custom 1,650-tonne capacity crane, to handle Sofia’s heaviest monopiles – each monopile forming the basis for a 252-metre-long Siemens Gamesa 14 MW turbine.

Sven Uttermoehl, CEO of RWE Offshore Wind, praised the achievement, cited: “The successful completion of the monopile installation in Sofia is an important milestone in the implementation of this complex offshore wind construction project. This achievement is a testament to the expertise, dedication and collaboration of our partners across the RWE Group. Sofia will play a key role in contributing to the UK’s clean energy transition and strengthening energy security.”

RWE advances Sofia offshore wind farm with industry-leading innovation and sustainable solutions

With the successful installation of all monopile foundations, a milestone in this regard, Van Oord has begun the next major phase at the Sofia offshore wind farm – the installation of approximately 360 km of array cables, which is expected to be completed by the end of 2025. Meanwhile, as we already know from the progress of turbine installation, 27 of the 100 Siemens Gamesa 14 MW turbines have already been installed – half of which with recyclable blades, reinforcing Sofia’s role as a global model for sustainable offshore wind.

Sofia, the first offshore wind project worldwide to commit to using Siemens Gamesa 14 MW turbines during its initial development, will demonstrate its leadership in technology adoption. This article provides a comprehensive overview of the technical and engineering innovations that will transform Sofia into a next-generation clean energy project.

Cutting-edge design and environmental innovation

A number of modern design innovations have been used and adapted. Here In contrast to traditional offshore foundations, separate transition pieces are used, with the design for Sophia using extended single-piece monopiles. Manufactured by EEW, this approach reduces total steel usage, reducing the project’s carbon footprint and material requirements.

In another UK first, the project has installed a full-scale bubble curtain noise abatement system for 34 foundation installations. Operated by Hydrotechnic Offshore, the technology protects marine species in the environmentally sensitive Southern North Sea Special Area of Conservation (SAC), helping to reduce underwater noise.

Port of Tyne 1.4 GW offshore Wind Farm

All offshore foundation elements were marshalled and stored at the Port of Tyne, where significant infrastructure investment is being made to meet the logistical needs of Sophia. This has enhanced the port’s role in future offshore wind developments across the North East of England.

Leading sustainable turbine technology

Next up in turbine technology, the reusable blades used on Sophia are made with a specialist resin system that enables full recyclability and mark the largest order of this type of blade at the time of purchase. The Turba initiative not only supports the circular economy but also paves the way for environmentally-conscious offshore wind development worldwide.

Increased grid capacity

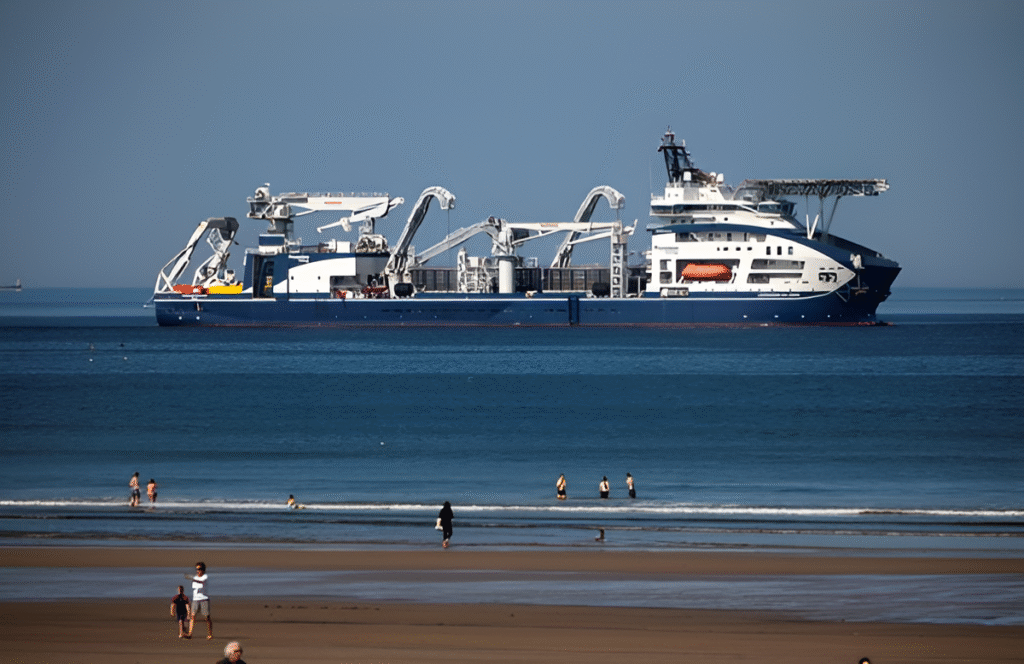

To maximize energy export efficiency, Sophia has increased its grid connection capacity from 1,000 MW to 1,320 MW, using advanced high-voltage direct current (HVDC) technology with voltage source converters. This allows for increased transmission capacity, helping to deliver cleaner energy to homes in the UK. And planning the world’s longest offshore export cable, spanning 220 kilometers, required highly specialized engineering to overcome the challenges of laying the infrastructure through complex seabed conditions.

World-class vessel and equipment installation

Sophia is set to be the first offshore wind farm to use the world’s most advanced cable-laying vessel, Prysmian’s Leonardo da Vinci. Equipped with:

- The highest cable carousel capacity on the market

- Double the industry-average capstan capacity

- A DP3 dynamic positioning system

- Hybrid propulsion and 90-day operational autonomy

The vessel will enable installation in water depths of up to 3,000 meters, making it ideal for the project’s demanding offshore environment.

Innovations in cable construction and sustainability

The onshore HVDC cable will incorporate a patented High-Performance Thermoplastic Elastomer (HPTE) insulation system—a fully recyclable, zero-emission process that reduces carbon emissions by 40% compared to conventional methods.

Onshore civil engineering contractor JMS has used innovative construction techniques to optimize efficiency and safety:

- V-buckets, which reduce trenching time and heavy equipment passes

- A duct trailer system that eliminates the need for workers in trenches when installing ducts

- A sand truck that reduces trenching time when installing cement-bound sand

Cutting-edge wind farm layout and infrastructure efficiency

The Sophia team has developed a highly optimized array layout to maximize energy production. The design of the offshore converter platform has also been significantly streamlined, using fewer materials and reducing overall project costs compared to previous designs used in Germany.

Strategic collaboration with the adjacent Dogger Bank Sea Wind Farm project is enabling Sophia to achieve cost-sharing and technological synergies, increasing efficiency in both developments.

Collaborative Procurement and Risk Management

Using a holistic, experience-led procurement strategy, RWE worked closely with potential supply chain partners at the pre-tender stage to align contract models. This approach allowed for effective risk allocation, ensuring the lowest possible overall project cost while maintaining high innovation standards. It also contributed to the record-breaking Levelized Cost of Energy (LCoE) for Sofia.

Regulatory Innovation and Environmental Protection

RWE has pioneered several advances in environmental management and compliance:

- Integrated LiDAR and sky digital survey for seabird monitoring – a novel application of proven technology for ornithological research.

- Proposed the use of low-order deflagration to neutralize unexploded ordnance (UXO), which significantly reduces underwater noise and marine impact compared to traditional detonations.

RWE is active in high-level environmental research initiatives such as ORJIP II and OWSMRF, which aim to close knowledge gaps and reduce compliance risks for future offshore projects.

Investing in UK offshore innovation through ORE Catapult

As part of its commitment to UK offshore wind innovation, SOFIA has supported the 2023 ORE Catapult Launch Academy, a nine-month programme designed to accelerate early-stage technology development. Ten UK-based companies have been selected, including:

- Aquatech Group, known for its innovative cable monitoring and protection

- Wildcat Films to Integrate Radar into Bird Survey

This collaboration will highlight Sophia’s commitment to nurturing the next generation of offshore wind technology and environmental solutions.

With its advanced design, sustainability-first approach and pioneering technology, the Sophia Offshore Wind Farm sets new industry standards and exemplifies how large-scale offshore wind can deliver clean, affordable and reliable energy. Once operational, this 1.4 GW wind farm is set to power 1.2 million UK homes, reinforcing RWE’s leadership in the global transition to renewable energy.

Sophia Offshore Wind Farm at a Glance

Total capacity: 1.4 GW

Offshore wind project location: 195 km off the north-east coast of the UK (Dogger Bank)

Total depth: 20-35 meters

Number of turbines: 100 x Siemens Gamesa 14 MW

Energy generated: around 1.2 million

Construction Stats: 2021

Expected to complete : 2025

Developer: RWE Offshore Wind

Frequently Asked Questions (FAQ)

What is the Sofia Offshore Wind Farm?

Sofia Offshore Wind Farm is a 1.4 gigawatt (GW) offshore wind project constructed by the RWE. Situated 195 kilometers from the UK’s northeast coast on Dogger Bank, it is one of the world’s biggest and most state-of-the-art offshore wind farm, and will power 1.2 million homes every year with renewable and clean energy.

The Sofia Offshore Wind Farm – who is building it?

Offshore wind power giant, RWE is leading the development and construction of the project. Among key suppliers are Van Oord, which will provide the foundation and the cable installation, and Siemens Gamesa which will deliver 14 MW wind turbines, complete with a recyclable blade design.

Sofia Offshore Wind Farm, where is it?

Sofia is situated 195 kilometres from shore at Dogger Bank in the North Sea around 195km off the coast of Teesside in the UK’s North Sea. It is located in water depths of 20-35 metres, on a sock the equivalent size to the Isle of Man – so one of the remotest and most challenging UK offshore wind farm developments to reach completion.

How many houses will be lit by the Sofia Wind Farm?

When fully operational, the Sofia Offshore Wind Farm will be capable of supplying power to around 1.2 million average UK homes, playing a major part in the UK’s ongoing transition to a clean, green energy system and providing the up to 1000 jobs the project is currently creating.

What sort of turbines are being used in the Sofia project?

The project features a total of 100 Siemens Gamesa 14 MW turbines, 50 of which have recyclable blades, marking a world first at this scale. The wind turbines are some of the largest on the market and are an impressive step in wind turbine technology.

What are the recyclable wind turbine blades — and why are they significant?

Recyclable wind turbine blades require a special-class resin system that can be broken down into individual materials at end of life. This will help advance a more sustainable offshore wind industry, reduce landfill waste and drive greater circular economy in the UK’s renewable energy efforts.

Which cable technologies are applied in the Sofia Wind Farm?

Sofia has both array and export cables. It will use 360 km of array cables and the longest ever offshore wind export cable in the world (220 km) using HVDC (High Voltage Direct Current) technology with voltage source converters. This enables more efficient power transmission and capacity is also up by 320 MW from 1000 MW.

What is HVDC technology and how can it benefit offshore wind farms?

The high voltage direct current (HVDC) transmission makes it possible to carry electricity for long distances at lower losses than the AC transmission. Sofia can deliver 1.32GW of wind power effectively to the UK grid and help meet renewable targets by using HVDC with VSC technology.

Sofia’s offshore wind cable installation: What’s so special?

Sofia is the first assignment of Leo, the world’s most advanced cable-laying vessel, which has started working on the project. It features:

Largest carousel capacity available

Hybrid propulsion for reduced emissions

Deep sea cables laying ability (up to 3,000 meters)

These new designs ensure that cable is laid more safely, efficiently and environmentally friendly.

What is Sofia doing to make construction less harmful to the environment?

Sofia has used bubble curtain noise mitigation systems during monopile installation in support of marine mammal conservation in the Southern North Sea Special Area of Conservation. It also employs low-order deflagration for UXO clearance, reducing impact on underwater noise.

Which ports and infrastructure does the Sofia Wind Farm use?

Foundation components and material are marshalled and distributed from the Port of Tyne. “The port has invested heavily into accommodating this major offshore wind development, which has significantly boosted the renewable energy supply chain in North East England.

What is RWE’s position in offshore wind on a global basis?

RWE is a global offshore wind development leader. The Sofia Offshore Wind Farm is currently the largest of RWE’s offshore wind farms under construction worldwide and one of the largest infrastructure projects in the UK, reinforcing the company’s ambition to play a part in the UK’s clean energy future and support its path to net zero.

What does the Sofia Wind Farm do to drive down costs of offshore wind energy?

Coupled with novel procurement strategies, innovative asset financing mechanisms, simplified converter station design, and a strategic collaboration with adjacent Dogger Bank C, Sofia has delivered market-leading levelized cost of energy (LCoE) offers, helping to reduce the costs of offshore wind.

What is the ORE Catapult Launch Academy and what role does Sofia have?

Sofia has backed the 2023 ORE Catapult Launch Academy, which aims to fast-track UK offshore wind innovation. The project chose firms from the UK in Aquatec Group and Wildcat Films to help drive forward cable protection systems and ornithological monitoring technologies.

Ismot Jerin is the founder and Editor-in-Chief of WindNewsToday, an independent publication covering offshore wind, renewable energy policy, and clean power markets with an analytical focus on the United States and global energy transition.